Opt for Prevost composite impact wrenches!

With its range of pneumatic tools, impact drivers, ratchet wrenches, power screwdrivers, sanders, grinders, drills, chisel hammers, cutting tools, specialist tools and accessories, Prevost offers a selection of technical products designed to withstand the demands of professional use in bodywork shops, garages, general mechanics, industry, metalwork, woodwork and more.

PRESENTATION OF IMPACT WRENCHES

Prevost proposes a range of composite impact wrenches featuring new heavy-duty double hammer technology delivering more power and reliability. Our impact wrenches are available in 3/8”, 1/2” and 3/4”. Their excellent power/weight ratio and their composite body offer ease of use (excellent thermal insulation) and easy handling (rotating connection, progressive trigger).

The silencer built into the handle makes for a more compact design and a lower sound level.

These impact wrenches have four tightening settings to provide the desired torque. The power is constant when loosening.

Tighten your bolts with the TIW C121150 impact wrench.

ARE YOU FAMILIAR WITH THE HEAVY-DUTY DOUBLE HAMMER MECHANISM?

The heavy-duty double hammer technology featured in our impact wrenches significantly prolongs the life span of the mechanism and boosts the tool's performance.

The rib separating the two hammers increases the strength of the cage, thereby offering great robustness. It prevents friction between the two weights and protects the hammers. The short, smooth power-up time with less vibration offers greater user comfort.

The separate double hammer mechanism offers great reliability and excellent balancing of the machine for professional use.

Exploded view of the heavy-duty double hammer mechanism of a Prevost composite.

HOW TO PROPERLY GAUGE TIGHTENING TORQUE?

It is important to remember that for optimum assembly, bolted parts must be appropriately tightened. We therefore recommend using the rated torque value, reached 3 to 5 seconds after starting to tighten, when choosing your tool. This value applies when the machine is used in normal conditions.

When selecting your tool, you should compare torque values under the same conditions: certain manufacturers promote their tools by stating torque values reached 10 to 15 seconds after the point of impact, which is not a fair reflection of actual use.

The impact wrench takes you as close as possible to the finishing point. As a safety precaution, we recommend finishing the tightening with a torque wrench or suitable spanner wrench such as the Prevost TIW C12L815 composite impact wrench with torque limiter.

A closer look at the tightening settings of a Prevost composite impact wrench with heavy-duty double hammer

CHOOSING THE BEST TOOL FOR THE APPLICATION

PREVOST's composite impact wrenches with double hammer technology are ideal for a great many applications, such as dismantling and assembling using bolts and screws. Certain models are available with an extended shaft for hard-to-reach areas.

PREVOST also offers compact impact wrenches for use in cramped areas in repair shops. Special heavy-duty aluminium impact wrenches are available for harsh and intensive applications.

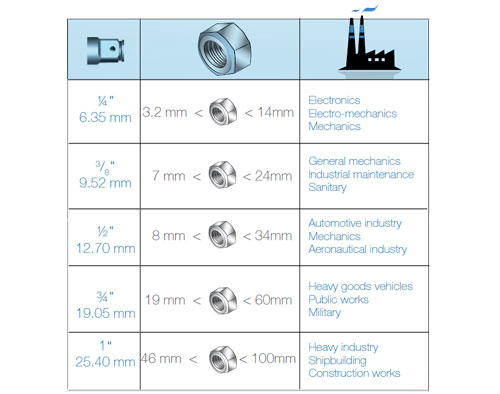

The size of the square drive is a decisive factor when choosing the right tool for the application.

See opposite for a summary of the solutions offered by PREVOST.

ENHANCING AND DIVERSIFYING THE USE OF YOUR PNEUMATIC IMPACT WRENCHES

TMH 15 magnetic tool holder and sockets for impact wrenches

PREVOST offers a range of accessories to improve your working comfort and to extend the possible applications. The following boxes of sockets are available for square impact wrenches:

- 3/8”: 8 chromium vanadium sockets from diameter 8 to 19 mm

- 1/2”: 14 chromium vanadium sockets from diameter 10 to 30 mm

- 3/4”: 8 chromium molybdenum sockets from diameter 26 to 38 mm

- 1”: 8 3/4 molybdenum sockets from diameter 26 to 38 mm

PREVOST also offers a functional and easy-to-move magnetic stand for tools and accessories.