Pitfalls to avoid when installing a compressed air supply in paint workshops

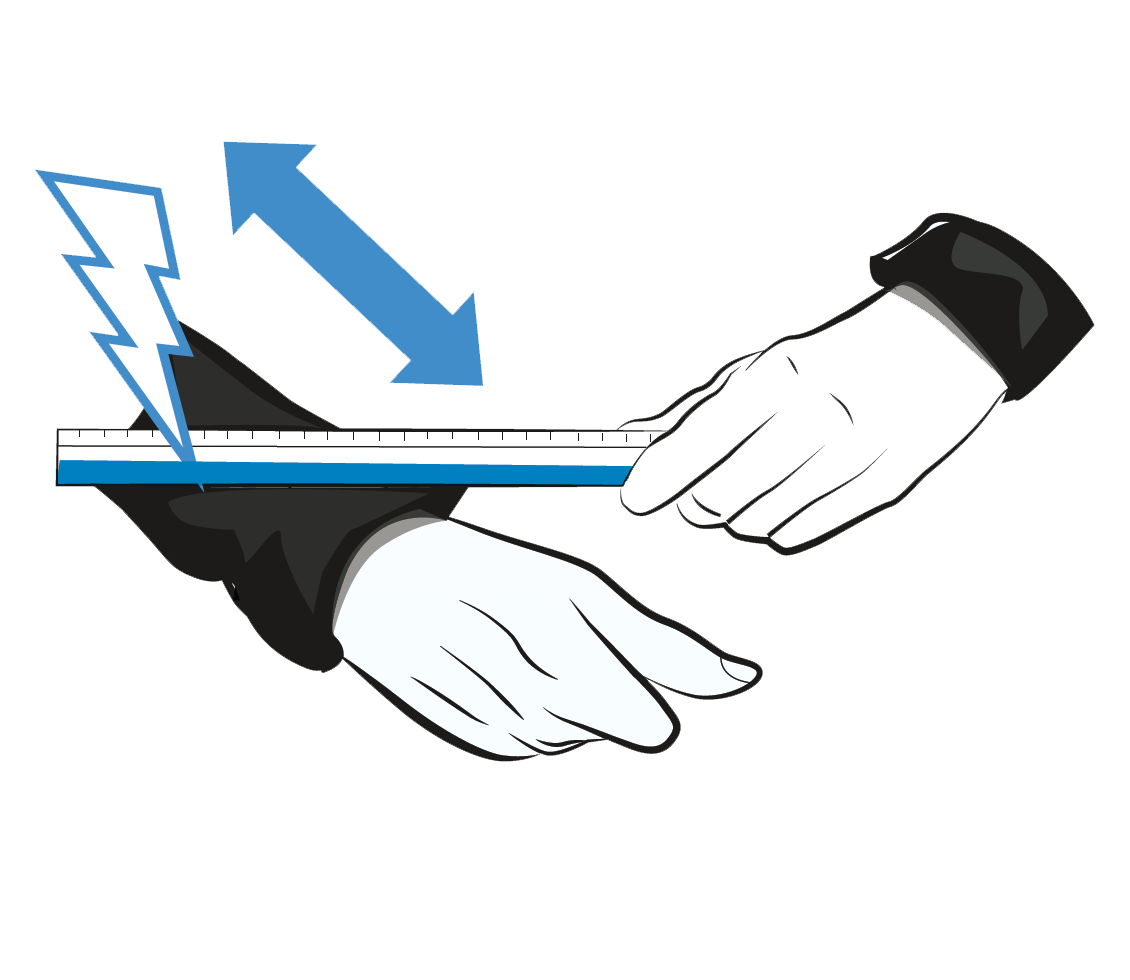

1 - Static electricity and compressed air

We have all seen static electricity in action, when we brush our hair, touch a car door, or rub a plastic ruler against a piece of fabric.

We know that the ruler will be charged with static electricity and attract small pieces of paper scattered around it.

This phenomenon also applies to compressed air when it circulates under pressure in a coupling or hose, and can cause serious accidents, including explosions and fires.

ENEMY NO. 1 IN A PAINT WORKSHOP

2 - Dust in the surrounding environment

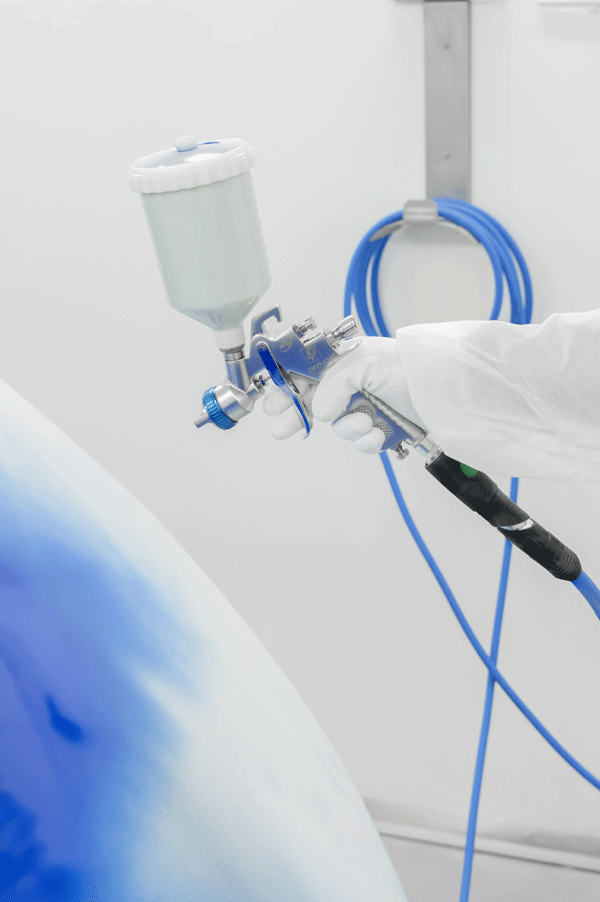

In a bodywork shop, paint guns operate using pneumatic energy. Compressed air is mixed with the paint and projected onto the workpiece in question. This energy is directed by means of plastic hoses in which static electricity can build up and compromise the painting process. As we said before, static electricity attracts any dust in the surrounding environment.

This residual contamination will stick to the freshly painted surface.

Rectifying this means re-doing the entire painting process, resulting in an overall loss for the bodyshop operator.

Temperatures and particulate

During the drying phase, the temperature is generally set at 60°C or more. This heat can damage the interior of the hoses if they are ill-suited to such temperatures, creating particulate matter that will be projected into the paint.

In order to avoid this type of incident, it is essential to use products suited to this environment. STOFLEX extension hoses made of SBR/EPDM rubber and fitted with prevoS1 quick safety couplings and adaptors are antistatic and withstand temperatures ranging from -15°C to 70°C.

3 - Craters and silicone

The presence of silicone in your air network, and therefore in paint, will create bubbles and craters, causing the dried paint to chip.

To prevent such problems, silicone-free products must be used.![]()

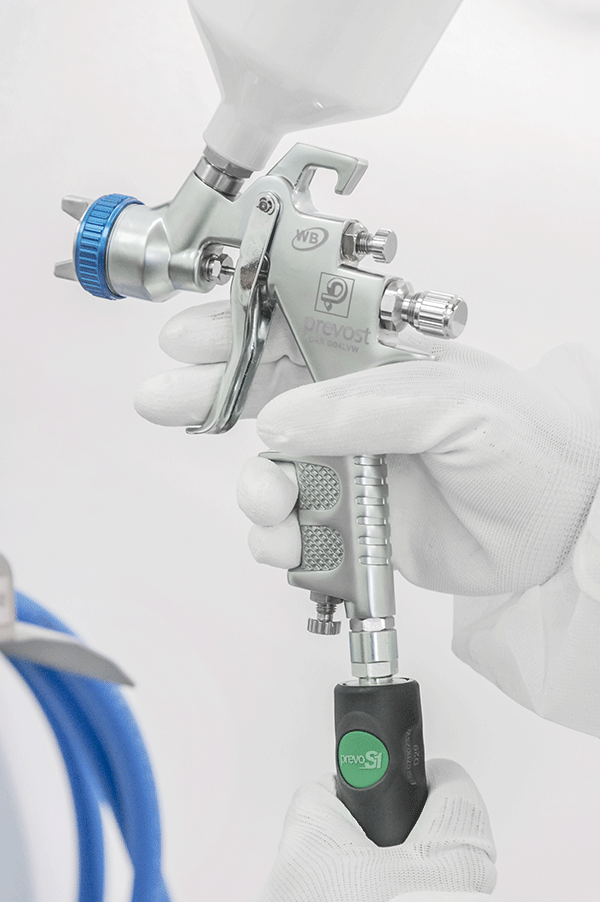

4 - The ATEX standard

The ATEX Directive on explosive atmospheres is a standard used to classify equipment according to the level of danger of its environment, in order to avoid the risks of explosion.

prevoS1 quick safety couplings meet the requirements of categories 2 and 3 of the ATEX standard, which certifies the use of prevoS1 products in most industries (included gaseous environments and paint booths).

They do not comprise any potential sources of ignition, enabling their use with equipment on sites presenting an explosion risk, such as flour transfer systems and gaseous environments.

5 - The right equipment for your workplace

When working with paint, it is essential that the workplace be equipped with :

• An air dryer at the head end or booth entry point, to eliminate all traces of humidity in the air (creation of craters)

• An air dryer at the head end or booth entry point, to eliminate all traces of humidity in the air (creation of craters)

• A submicron filtration system with a regulator (to avoid the risk of the “orange peel” effect and craters)

• An appropriate paint spray gun (correct nozzle size, operating pressure, flow rate, etc.)

• An appropriate paint spray gun (correct nozzle size, operating pressure, flow rate, etc.)

• Extensions hoses that are antistatic, silicone-free and resistant to high temperatures

• Safety quick couplings that are anti-static, silicone-free, resistant to high temperatures

• Safety quick couplings that are anti-static, silicone-free, resistant to high temperatures

REQUEST PREVOST TRAINING

Are you a professional (design office engineer, maintenance technician, installer, energy supplier, sales school, etc.) seeking to incorporate proficiency in compressed air systems into your production or marketing strategy?